18 Jan

How is the Structural Integrity of Aluminium Tested?

Usually, a combination of mechanical and load-bearing tests is used to evaluate the structural integrity of aluminium lighting columns. The column's resistance to environmental stressors, such as wind loads and impact forces, is assessed by these tests. Static load tests, in which the column is subjected to a predetermined weight, and dynamic tests, which mimic actual environmental circumstances like wind resistance or seismic activity, are examples of testing techniques. To evaluate the column's longevity over time, fatigue tests may also be performed. To make sure it satisfies the necessary strength and safety requirements, the aluminum's material composition—including the alloy used—is further evaluated.

Do Aluminium Lamp Posts Meet Wind Load Requirements?

Yes, aluminium lamp posts are designed to meet wind load requirements, especially in areas with high winds or coastal conditions. The wind load capacity depends on the height and design of the column, as well as the type of light fixture mounted on top. Manufacturers typically calculate the wind load resistance based on local climate conditions and regulations. To ensure safety and performance, aluminium lamp posts are engineered to withstand wind speeds typically ranging from 80 to 130 km/h, but can be designed for higher speeds if required. Reinforced aluminium alloys and additional structural components are often used for areas subject to extreme weather conditions.

What Are the Safety Features of Aluminium Lighting Columns?

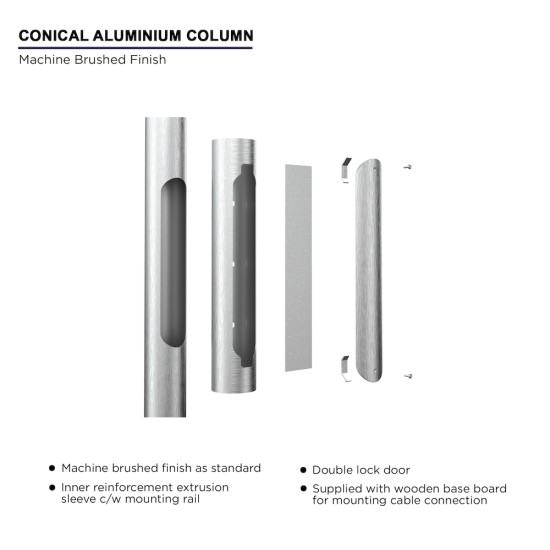

A number of safety elements are included into aluminium lighting columns to guarantee their functionality and guard against possible risks. One important aspect is the use of coatings that are resistant to corrosion, including powder coating or anodising, which helps stop deterioration from exposure to the environment. Additionally, aluminium columns are built to be stable, meaning they can withstand impacts and strong winds. Electrical cabling inside the lighting column is frequently enclosed in waterproof enclosures for enhanced safety in order to guard against moisture damage and short circuits. The base of the column is usually made to reduce the chance of injury in the case of a collision in places where there is a lot of foot traffic.

Leave a Comment